Category

Dual Plate Wafer Check Valves Non Return Full EPDM NBR Rubber Lining Seat

Overview Butterfly Valve Series Product Parameters STANDARD MATERIALS OF MAIN PARTS DIMENSIONS PRESSURE TEST ISO5211 Top

Overview

STANDARD MATERIALS OF MAIN PARTS

DIMENSIONS

PRESSURE TEST

ISO5211 Top Flange & Shaft Data

Product Features

1. The valve structure is simple, casting letters are clear, smooth surface.2. Light torque easy to open, it can serve long time.3. All parts are machined accurately, quality is much better.4. We adopt better quality rubber seat for long service life.5. Replaceable seat, it is easy to mend the valve.

Q:Could you offer a free sample ?

A:We can provide free samples for you to evaluate, but you need to bear their shipping costs.

Q:Are you a facrory or trade company ?

A:We are a marine butterfly valve manufacturer, and specialize in the production and export of valves for more than ten years

Q:Would you have a discount if l have a large order? A:Yes we could offer different discount according to your order quantity

Q:How will you make the shipment? A:By sea shipment/Air/Express service.

Q4:Do you accept OEM business? A4:Yes.We do.

Basic Info.

| Model NO. | Newton-2 |

| Working Temperature | Normal Temperature (-40°C<T<120°C) |

| Material of Seal Surface | Soft Sealed |

| Valve Body | Casting |

| Standard | Pn10/Pn16/10K/150lb |

| Application | Industrial Usage, Water Industrial Usage, Marine |

| Seat Type | Bonded Seat/Common Seat |

| Plate | Di+Ni, CF8, CF8m, Bronze |

| Body | Ci/Di |

| Body Bearing | PTFE |

| Body Seat | NBR, EPDM, Viton, Neoprene |

| Plug | Carbon Steel |

| Spring | Ss |

| Place of Origin | Tianjin, China |

| Packing | Wooden Box |

| Working Pressure | Pn10/Pn16/10K/150lb |

| OEM | Accepted |

| Warranty | 18 Months |

| Color | Customized Color |

| Transport Package | Plywood Case |

| Specification | DN40-DN1200 |

| Trademark | NEWTON |

| Origin | Tianjin |

| HS Code | 8481804090 |

| Production Capacity | 10000000 Sets Per Year |

Product Description

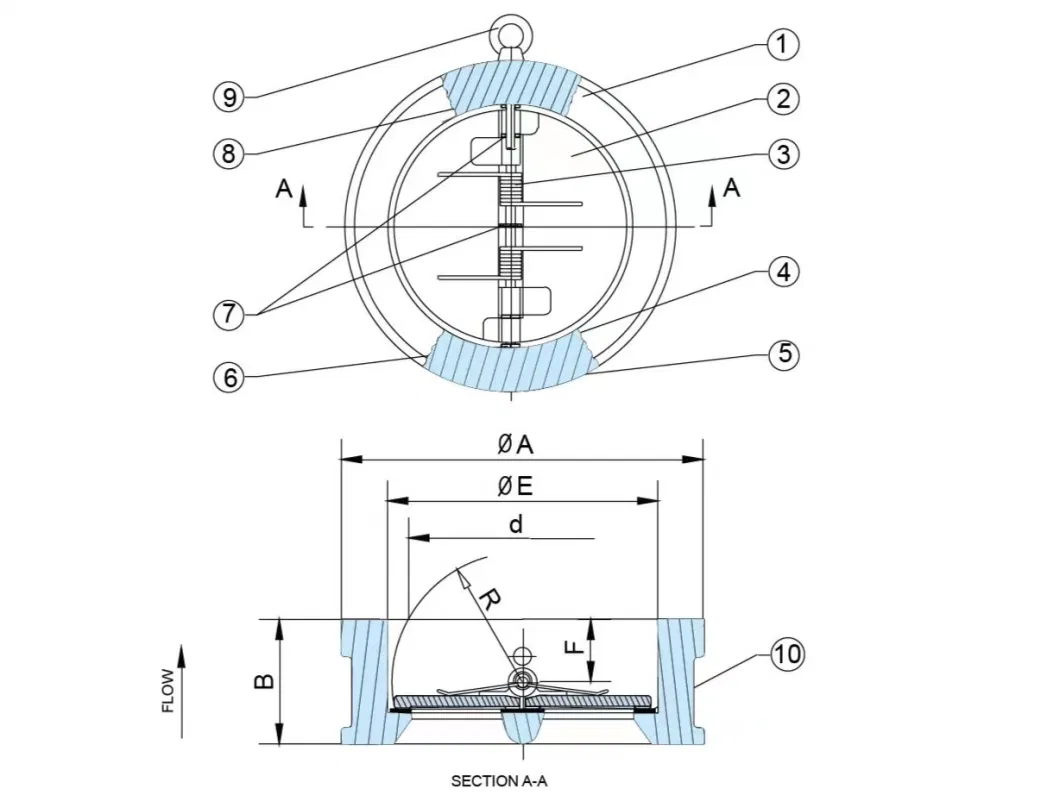

Butterfly Valve SeriesProduct Parameters

| NO. | Item | Standard |

| 1 | SIZE | DN40-1200 |

| 2 | Face to Face | DIN 3202 k3, API 594 150LB |

| 3 | Connection Flange | DIN, BS, UNI, ISO, ANSI, AS, JIS |

| 5 | Working Pressure | PN10/PN16/PN25 |

| 6 | Application | Fresh Water, Sea Water, Oil, Gas, Acid, Food, Steam |

| 7 | Application Temperature | -10ºC-120ºC |

| 9 | Seat Type | Bonded Seat, Commen Seat |

STANDARD MATERIALS OF MAIN PARTS

| NO. | PART | MATERIAL |

| 1 | Body | Cast Iron(GG25), Ductile Iron(GGG40/50) |

| 2 | Plate | DI+Ni, CF8, CF8M, Bronze |

| 3 | Spring | Stainless Steel |

| 4 | Hinge Pin | Stainless Steel |

| 5 | Plug | Carbon Steel |

| 6 | Body Bearing | PTFE |

| 7 | Spring Bearing | PTFE |

| 8 | Stop Pin | Stainless Steel |

| 9 | Eye Bolt | Carbon Steel |

| 10 | Body Seat | NBR, EPDM, Viton, Neoprene |

DIMENSIONS

| SIZE | B | E | F | R | d | A | ||

| in | DN | DIN PN10/16 | ANSI150 | |||||

| 2 | 50 | 43 | 65 | 19 | 28.8 | 43.3 | 107 | 102 |

| 2-1/2 | 65 | 46 | 80 | 20 | 36.1 | 60.2 | 127 | 121 |

| 3 | 80 | 64 | 94 | 28 | 43.4 | 66.4 | 142 | 133 |

| 4 | 100 | 64 | 117 | 27 | 52.8 | 90.8 | 162 | 171 |

| 5 | 125 | 70 | 145 | 30 | 65.7 | 116.9 | 192 | 193 |

| 6 | 150 | 76 | 170 | 30 | 78.6 | 144.6 | 218 | 219 |

| 8 | 200 | 89 | 224 | 31 | 104.4 | 198.2 | 273 | 276 |

| 10 | 250 | 114 | 265 | 33 | 127 | 233.7 | 328 | 336 |

| 12 | 300 | 114 | 310 | 50 | 148.3 | 283.9 | 378/382 | 406 |

| 14 | 350 | 127 | 360 | 43 | 172.4 | 332.9 | 438/442 | 448 |

| 16 | 400 | 140 | 410 | 45 | 197.4 | 381 | 488/495 | 511 |

| 18 | 450 | 152 | 450 | 52 | 217..8 | 419.9 | 538/555 | 546 |

| 20 | 500 | 152 | 505 | 58 | 241 | 467.8 | 592/617 | 603 |

| 24 | 600 | 178 | 624 | 73 | 295.4 | 572.6 | 695/734 | 714 |

| 28 | 700 | 229 | 720 | 98 | 354 | 680 | 809 | 828 |

| 32 | 800 | 241 | 825 | 100 | 398 | 770.5 | 916 | 936 |

PRESSURE TEST

| Nominal Diameter | DN25-DN1200 | 1''- 48'' | DN25-DN1200 | 1''- 48'' |

| Nominal Pressure | 1.0 Mpa | 150 Psi | 1.6 Mpa | 250 Psi |

| Seal Test Pressure | 1.1 Mpa | 165 Psi | 1.76 Mpa | 275 Psi |

| Shell Test Pressure | 1.5 Mpa | 225 Psi | 2.4 Mpa | 375 Psi |

| Pressure Conversion | 1 Mpa=1, Bar=15Psi, PN20=Class 150 | |||

ISO5211 Top Flange & Shaft Data

Product Description

Product Features

1. The valve structure is simple, casting letters are clear, smooth surface.2. Light torque easy to open, it can serve long time.3. All parts are machined accurately, quality is much better.4. We adopt better quality rubber seat for long service life.5. Replaceable seat, it is easy to mend the valve.

Certifications

Packaging & Shipping

Pictures

Company Profile

Tianjin Newton Valve Co., Ltd is a professional valve manufacturer of rubber seat butterfly valve, wafer check valve, ball check valve, resilient seat gate valve, cast iron valves for marine, Y strainer.

We adpot advanced, efficient, careful manage system to ensure that we can produce high-quality products in time, experieced sales team, perfect after-sales support to satisfy clients. We adheres to " Newton use science to do better valves, focus on details, continuous improvement" which makes us in an invincible position in the fierce market competition. We believe that we will do the better quality products, supply most perfect service for you.FAQ

Q:Could you offer a free sample ?

A:We can provide free samples for you to evaluate, but you need to bear their shipping costs.

Q:Are you a facrory or trade company ?

A:We are a marine butterfly valve manufacturer, and specialize in the production and export of valves for more than ten years

Q:Would you have a discount if l have a large order? A:Yes we could offer different discount according to your order quantity

Q:How will you make the shipment? A:By sea shipment/Air/Express service.

Q4:Do you accept OEM business? A4:Yes.We do.